Silicon Molybdenum Bar

Tlhaloso ea Sehlahisoa

Molamu oa silicon molybdenum

Silicon Molybdenum Rod resistance heat element e thehiloe ho molybdenum disilicide e le thepa e tala, e nang le litšobotsi tsa ho hanyetsa mocheso o phahameng le ho hanyetsa oxidation.Ha e sebelisoa moeeng oa mocheso o phahameng oa oxidation, filimi ea khalase e khanyang le e teteaneng ea quartz (SiO2) e thehoa holim'a metsi, e ka sireletsang karolo e ka hare ea molamu oa silicon molybdenum ho tloha ho oxidation.Lintho tsa silicon molybdenum rod li na le khanyetso e ikhethang ea mocheso o phahameng oa oxidation.

| Lebitso la lihlahisoa | Silicon Molybdenum Bar |

| Botenya | 5.6–5.8g/cm3 |

| Matla a flexural | 20MPa(20℃) |

| Vickers hardness (HV) | 570kg/mm2 |

| porosity | 0.5–2.0% |

| ho monya metsi | 0.5% |

| Thermal elongation | 4% |

| ho felloa ke matla | 0.7~0.8(800℃2000℃) |

Kopo

Lithupa tsa silicon molybdenum li sebelisoa haholo e le lisebelisoa tsa ho futhumatsa

Lihlahisoa tsa silicon molybdenum rod li sebelisoa haholo ho metallurgy, ho etsa tšepe, khalase, ceramics, refractory, kristale, lisebelisoa tsa elektroniki, lipatlisiso tsa thepa ea semiconductor, tlhahiso le likarolo tse ling, haholo-holo bakeng sa lirafshoa tse sebetsang hantle tse sebetsang hantle, likristale tsa maiketsetso tsa boemo bo holimo, meaho e nepahetseng. Tlhahiso ea li-cermets, likhoele tsa khalase, likhoele tsa optical le litšepe tsa alloy tsa boemo bo holimo.

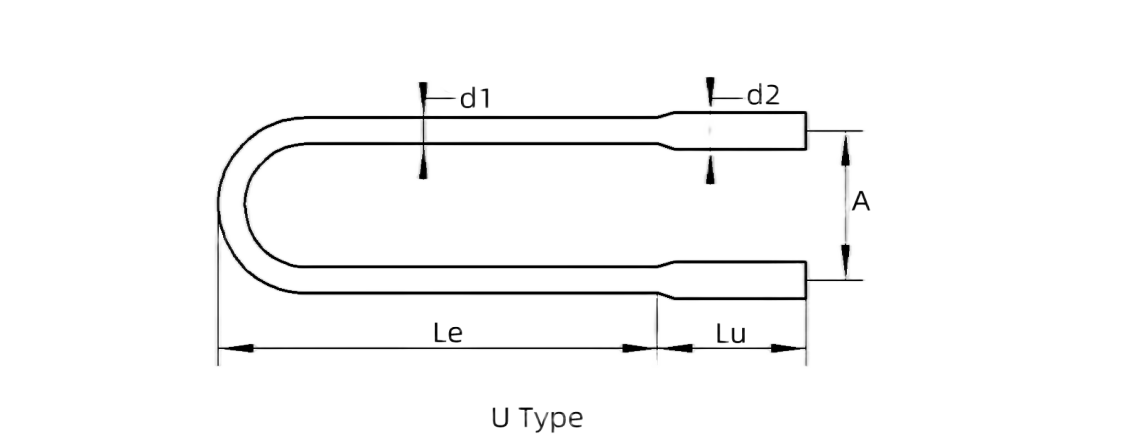

Boholo bo tloaelehileng

| Qetellong e chesang diameterd1 | Qetello e batang ka bophara2 | Hot end length Le | Bolelele ba pheletso e batangLu | Sebaka A |

| 3mm | 6mm | 80-300 limilimithara | 80-500 limilimithara | 25 limilimithara |

| 4mm | 9mm | 80-350 limilimithara | 80-500 limilimithara | 25 limilimithara |

| 6mm | 12 limilimithara | 80-800 limilimithara | 80-1000 limilimithara | 25-60 limilimithara |

| 7mm | 12 limilimithara | 80-800 limilimithara | 80-1000 limilimithara | 25-60 limilimithara |

| 9mm | 18mm | 100-1200 limilimithara | 100-2500 limilimithara | 40-80 limilimithara |

| 12 limilimithara | 24 limilimithara | 100-1500 limilimithara | 100-1500 limilimithara | 40-100 limilimithara |

Ha u na boholo boo u bo hlokang?

Ha ho bothata, sehlahisoa sena se ka etsoa ho latela boholo boo u bo hlokang

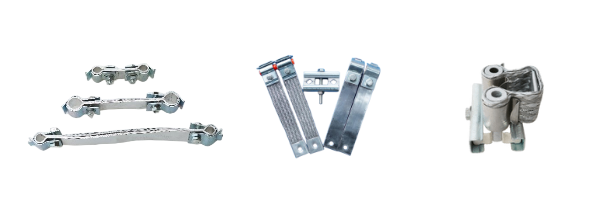

Ke eng hape eo re ka fanang ka eona

Re ikemiseditse ho rarolla mathata a theko bakeng sa bareki ba rona.Ha e le hantle, boholo ba nako u ka 'na ua hloka ho khutlela morao le morao pakeng tsa barekisi ba bangata, empa re u fa litšebeletso tse bonolo haholoanyane.

Ho feta lithupa tsa silicon molybdenum.Re ka boela ra hlahisa lisebelisoa tse kang aluminium foil braiding, silicon molybdenum rod plug litene joalo-joalo.Ke taba ea ho rarolla bothata ba ho reka thepa, ‘me ha re so etse ho lekaneng, re ntse re e sebetsa.

Lintlha tsa Odara

Lipotso le litaelo li lokela ho kenyelletsa lintlha tse latelang:

☑ Moetso oa D1/ D2 / Le/ Lu/ A parameter boleng, Mehlala: U Shape, Material Grade 1800, D1=3mm, D2=6mm, Le=140mm, Lu=125mm, A=25mm, e hlalosoa e le Hlalosa e le: MS18, Sebopeho sa U, 3/6×140×125×25.

☑ Mofuta oa W le mefuta e meng ea lithupa tsa silicon molybdenum li ka etsoa ho latela litšoantšo.