Ho roala ha PVD

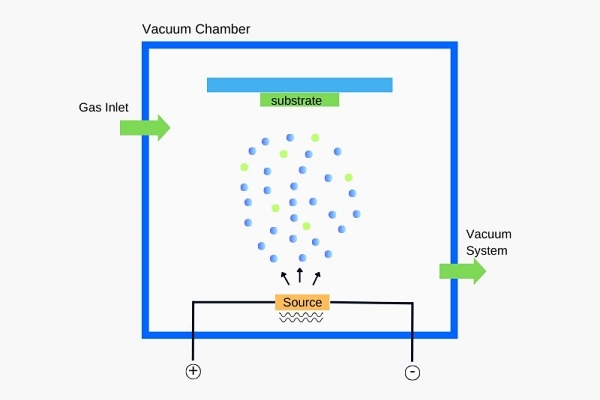

Theknoloji ea PVD (Physical Vapor Deposition) e bua ka theknoloji e sebelisang mekhoa ea 'mele tlas'a maemo a vacuum ho etsa mouoane oa mehloli ea lintho hore e be liathomo tse nang le khase kapa limolek'hule, kapa ho li kenya ka mokhoa o itseng ho li-ion, le ho beha filimi e tšesaane e nang le mesebetsi e itseng e khethehileng holim'a substrate. .

Theknoloji ea PVD ke theknoloji e ka sehloohong ea phekolo ea holim'a metsi e sebelisoang haholo ho fetola bokaholimo, ts'ebetso, mokhabiso, joalo-joalo ea thepa liindastering tse fapaneng.

Mekhoa ea mantlha ea ho beha mouoane oa 'mele e kenyelletsa:

›Mouoane oa vacuum

›Ho roala ha metsi

›Ho roala ka plasma ea Arc

›Ho roala ka ion

Re fana kaMouoane oa mochesoleMouoane oa lekhama la elektronelisebelisoa tse amanang le tsona, ho kenyeletsoa li-electron beam crucible liners, tungsten evaporation filaments, electron gun tungsten filaments, likepe, thepa ea mouoane, joalo-joalo.

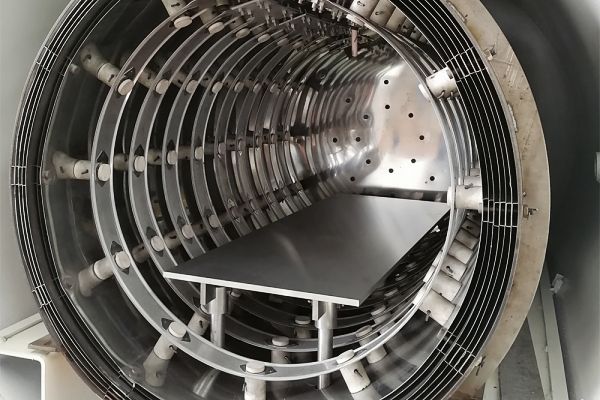

Sebōpi sa Vacuum

Lisebelisuoa tsa vacuum li sebelisoa haholo-holo bakeng sa ho chesoa ka ceramic, ho qhibilihisa vacuum, likarolo tsa vacuum tsa motlakase, ho senya likarolo tsa tšepe, ho tiisa tšepe ea ceramic, ho kenya mouoane oa 'mele (PVD), joalo-joalo.

Re fana ka lisebelisoa tsa ho futhumatsa, likepe le bajari, lithebe tsa mocheso, li-crucible liners, lithapo tsa tungsten, le mehloli ea mouoane, likarolo tse entsoeng, li-fasteners, joalo-joalo Thepa ke tungsten, molybdenum, kapa tantalum, e ka etsoang ka mokhoa o ikhethileng.

Photovoltaic & Semiconductor

Sebōpi sa khōlo ea kristale e le 'ngoe, e tsejoang hape e le sebōpi sa silicon crystal growth or silicon ingot furnace, ke lisebelisoa tse khethehileng tse sebelisoang indastering ea photovoltaic le ea semiconductor ho hlahisa li-ingots tsa silicon tsa kristale tsa boleng bo phahameng.

Monocrystalline silicon ke thepa ea mantlha ea ho etsa lisebelisoa tsa semiconductor joalo ka li-circuits tse kopaneng (ICs), lisele tsa letsatsi le li-sensor.

"Czochralski mokhoa" hona joale ke mokhoa o sebelisoang ka ho fetisisa oa ho lokisetsa silicon e le 'ngoe ea kristale.

Re fana ka lithupa tsa peo ea molybdenum, li-tungsten le li-crucible liner tsa molybdenum, li-fasteners, lihoko tsa molybdenum, lihamore tsa tungsten carbide, joalo-joalo.

Khalase Le Lefatše le Rare

›Indasteri ea Khalase

Re fana ka li-electrode tsa molybdenum bakeng sa ho qhibiliha ha khalase.

Li-electrode tsa rona tsa molybdenum li entsoe ka lithupa tse 99.95% tse hloekileng haholo tsa molybdenum.

Boholo ba li-electrode tsa Molybdenum: φ20-152 * L (yuniti: mm), re ka fana ka sebaka se hlatsoitsoeng sa alkali, se entsoeng ka mochine, joalo-joalo.

›Indasteri ea Lefatše e Rare

Indasteri ea lefatše e sa tloaelehang e kenyelletsa ho ntšoa, ho sebetsa le ho sebelisoa ha lintho tse sa tloaelehang tsa lefatše, e leng likarolo tsa bohlokoa tsa mahlale a fapaneng a tsoetseng pele le ts'ebeliso.

Re ka fana ka li-tungsten, molybdenum, le lisebelisoa tsa ho futhumatsa tsa tantalum, tungsten ea sintered, molybdenum crucibles, graphite crucibles, joalo-joalo.

Lisebelisoa le Methara

›Metal diaphragm: E sebelisoa haholo litekanyong tsa khatello ea diaphragm le li-transmitters. Lisebelisoa tseo re li hlahisang li kenyelletsa SS316L, tantalum, titanium, HC276, Monel400, le Inconel625.

› Elektrode ea lets'oao: Haholo-holo e sebelisoa ho li-electromagnetic flow metres. Eleketrode boholo ke M3 ~ M8, 'me thepa e kenyeletsa SS316L, tantalum, titanium, le HC276.

› Electrode e ka tlase (lesale la fatše):Haholo-holo e sebelisoa bakeng sa li-flowmeters tsa motlakase, hangata li sebelisoa ka bobeli. Boholo bo tloha ho DN25 ho isa ho DN600, 'me lisebelisoa li kenyelletsa SS316L, tantalum, titanium, le HC276.

›Diaphragm seal: se sebedisoang ho arola elemente ya ho metha ho se mahareng. Lisebelisoa tsa diaphragm tseo re li hlahisang li kenyelletsa SS316L, titanium, HC276, le tantalum. ASME B 16.5, DIN EN 1092-1, le litekanyetso tse ling tse teng.

› Lesale la ho phunya:e sebelisoang bakeng sa litiiso tsa diaphragm tse hoketsoeng ka flange, tse ka tlosang litšila holim'a diaphragm ka ho li hlatsoa le ho li hloekisa.

› Tube ea tšireletso ea Thermocouple:e sebelisetsoang ho sireletsa li-thermocouples bakeng sa tšebeliso e tloaelehileng lits'ebetsong tse fapaneng tsa indasteri. Re fana ka li-tubes tse sireletsang lisebelisoa tse latelang: tungsten, molybdenum, le tantalum.

Ka kopo ikopanye le rona kapa sheba sebaka sa rona sa marang-rang bakeng sa lintlha tse ling le lihlahisoa.

Iteanye le rona

Amanda│Mookameli oa thekiso

E-mail: amanda@winnersmetals.com

Mohala: +86 156 1977 8518 (WhatsApp/Wechat)

Haeba u ka rata ho tseba lintlha tse eketsehileng le litheko tsa lihlahisoa tsa rona, u seke oa tsilatsila ho ikopanya le mookameli oa rona oa thekiso (Amanda), o tla u araba kapele kamoo ho ka khonehang (hangata ha ho fete lihora tse 12), kea leboha. .