Ho koahela ka vacuum, ho tsejoang hape e le ho beoa ha filimi e tšesaane, ke ts'ebetso ea kamore ea vacuum e sebelisang lesela le tšesaane haholo le le tsitsitseng holim'a substrate ho e sireletsa matleng a ka e senyang kapa a fokotsang katleho ea eona. Ho koahela ka vacuum ho tšesaane, ho pakeng tsa li-micron tse 0.25 le tse leshome (li-inchi tse 0.01 ho isa ho tse 0.4).

Mefuta e meraro ea ho roala ka lephaka:

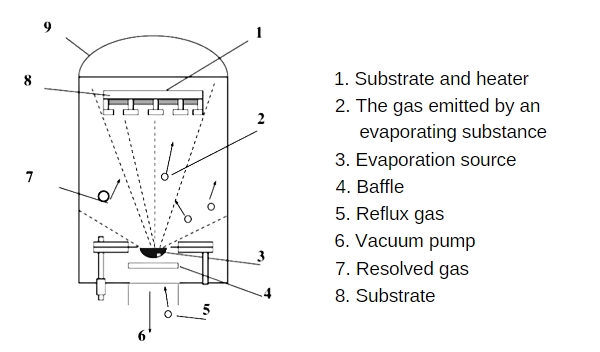

Seaparo sa mouoane

Ka har'a vacuum, evaporator e sebelisoa ho futhumatsa thepa e mouoane ho e kenya ka tlas'a lefatše, 'me phallo ea granular e mouoane e lebisoa ka ho toba ho substrate ebe e beoa holim'a eona ho etsa filimi e tiileng, kapa mokhoa oa ho koahela ka vacuum o sebelisoa ho futhumatsa le ho monya thepa e koahetsoeng. Khamphani ea rona e khona ho fana ka li-evaporator le likarolo tsa ho futhumatsa, ho kenyeletsoa le lijana tse fapaneng tse entsoeng ka litšepe tse hanyetsang tse kang tungsten, molybdenum le tantalum, hammoho le lithapo tsa tungsten le likhoele tsa tungsten bakeng sa ho futhumatsa.

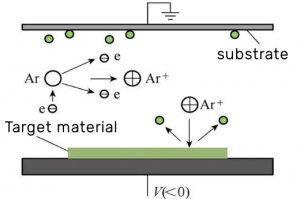

Ho roala ka ho phunya

Ka har'a vacuum, bokaholimo ba sepheo bo tlatsoa ka likaroloana tse nang le matla a mangata, 'me likaroloana tse tlatsoang li tlatsoa holim'a substrate. Hangata, thepa e tla kenngoa e etsoa thepa ea poleiti, jj., 'me lintho tse hanyetsang tse kang tungsten, molybdenum, tantalum, le titanium li ka tlatsoa. Khamphani ea rona e ka fana ka poleiti ea tungsten e hloekileng haholo, poleiti ea molybdenum, poleiti ea tantalum, poleiti ea titanium le lisebelisoa tse fapaneng tsa sepheo, tse ka sebelisoang bakeng sa ho tlatsoa ka sputtering.

Sekoahelo sa Ion

Ho betla ha ion ke ho sebedisa kgase e tswang ho yona ho etsa hore khase kapa thepa e monyehileng e be ionishe tlasa maemo a vacuum le ho kenya thepa e monyehileng kapa reactant ya yona hodima substrate ha di-ion tsa khase kapa di-ion tsa thepa e monyehileng di ntse di tjheswa. Ntle le ditshipi tse seng tsa ferrous, thepa ya ho betla ya vacuum e boetse e kenyelletsa tse seng tsa tshepe, e leng di-oxide, di-oxide tsa silicon le di-oxide tsa aluminium.

Mekhoa ea nakong e tlang

Ka nts'etsopele ea mahlale le theknoloji ea sejoale-joale, theknoloji ea ho koahela ka vacuum e sebelisoa haholo, ha e bapale karolo ea bohlokoa feela lisebelisoa tsa elektroniki tsa bareki, lipotoloho tse kopantsoeng, likarolo tsa optoelectronic tsa optical le masimo a mang, empa hape le lisebelisoa tsa bongaka, lifofane, matla a letsatsi, polasetiki, liphutheloana, masela, mechini, ho thibela maiketsetso, kaho le masimo a mang.

BAOJI Winners Metal e ka fana ka sebopi sa ho etsa mouoane joalo ka tungsten, molybdenum, tantalum, jj., sekepe sa mouoane, thepa e reretsoeng ho phunya (tungsten, molybdenum, tantalum, Niobium, titanium, jj.), terata ea tungsten ea sethunya sa elektrone, hitara ea tungsten le lintho tse ling tse sebelisoang ho koahela ka vacuum, lisebelisoa. Ka kopo ikopanye le rona bakeng sa tlhaiso-leseling e batsi (Whatsapp+86 156 1977 8518).

Nako ea poso: Phato-02-2022