Motsoako oa TZM hajoale ke sesebelisoa se setle ka ho fetisisa sa molybdenum alloy. Ke tharollo e tiileng e thatafalitsoeng le e matlafalitsoeng ke likaroloana tsa molybdenum, TZM e thata ho feta tšepe e hloekileng ea molybdenum, 'me e na le mocheso o phahameng oa recrystallization le khanyetso e betere ea ho thekesela, mocheso oa recrystallization o ka bang 1400 ° C, o phahameng haholo Bakeng sa molybdenum, e ka fana ka bokhoni bo betere ba ho solder.

MHC ke motsoako oa molybdenum o ntlafalitsoeng ke likaroloana o nang le hafnium le carbon. Ka lebaka la kabo e tšoanang ea li-carbide tse ntle haholo, thepa ena e ntse e bontša melemo ea ho hanyetsa mocheso hantle le ho hanyetsa ho thekesela mochesong oa 1550 °C, 'me mocheso o phahameng o khothaletsoang oa ts'ebetso le oona o phahame ka 150 °C ho feta oa TZM. Mohlala, ho extrusion dies, e ka mamella meroalo e feteletseng ea mocheso le ea mechine, kahoo thepa ea MHC e khothaletsoa bakeng sa lits'ebetso tsa ho etsa tšepe.

Motsoako oa molybdenum-zirconium, o nang le zirconia e nyane (ZrO2) ka har'a molybdenum e hloekileng, o ka eketsa khanyetso ea ho bola le khanyetso ea ho thekesela ha molybdenum.

Ho eketsa dielemente tse sa tlwaelehang tsa lefatshe ho ke ke ha ntlafatsa feela mocheso wa ho kgutliswa ha dikristale le ho hanyetsa ho kgephoha ha molybdenum ka mocheso o phahameng, empa hape ho ka fokotsa haholo mocheso wa phetoho ya polasetiki-brittle ya molybdenum, ho eketsa ductility, le ho ntlafatsa ho tetebela ha mocheso wa kamore le ho hanyetsa ho thekesela ha molybdenum ka mocheso o phahameng.

Kopo

Ka lebaka la matla a eona a matle a mocheso o phahameng, mocheso o phahameng oa ho nchafatsa le ho tsamaisa mocheso hantle, motsoako oa TZM o sebelisoa haholo libakeng tsa lifofane, lifofane le masimo a mang, joalo ka thepa ea nozzle, thepa ea nozzle, 'mele oa valve ea khase, phaephe ea phaephe ea khase. E ka boela ea sebelisoa e le likarolo tsa anode tse potolohang tsa X-ray, hlobo ea ho lahla ka tšohanyetso le hlobo ea extrusion, likarolo tsa ho futhumatsa le lithebe tsa mocheso ka har'a lionto tsa mocheso o phahameng.

Litšepe tse kopantsoeng tsa MHC li sebelisoa haholo lits'ebetsong tsa ho etsa tšepe:

● Terata ea molybdenum e sa tloaelehang e sebelisoa haholo-holo e le filament ea mohloli oa leseli la motlakase, electrode ea EDM le karolo ea ho futhumatsa ea ontong ea mocheso o phahameng.

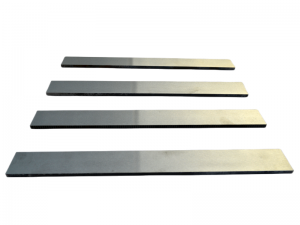

● Lipoleiti le maqephe a molybdenum a sa tloaelehang li sebelisoa e le li-wafer bakeng sa ho hatakela ka har'a li-thyristors, hammoho le litširelo tsa mocheso le maqephe a tataiso bakeng sa lipeipi tsa elektroniki.

● Motsoako oa molybdenum o sa tloaelehang o ka sebelisoa e le hlooho ea tšepe e chesang e phunyeletsang, hammoho le lisebelisoa tsa indasteri ea lifofane le ea nyutlelie, lipheo tsa lipalo tsa X-ray, li-dies tsa ho lahla die le li-dies tsa extrusion.

● Lihlahisoa tse bōpehileng joaloka rare earth molybdenum li sebelisoa e le li-electrode tse qhibilihang ka khalase, li-electrode tse qhibilihang tsa rare earth, li-crucible, likepe tse futhumatsang mocheso o phahameng, litširelo tsa mocheso oa mahlaseli a mocheso o phahameng, likou tsa phallo, li-rails tse tataisang, li-pad, jj.

● Li-alloy tsa molybdenum tse sa tloaelehang li ka boela tsa sebelisoa e le thepa ea cathode e chesang bakeng sa li-tube tsa elektroniki tse matla a mahareng le a phahameng. Thepa ea cathode ea molybdenum e sa tloaelehang e nkela sebaka sa cathode ea tungsten ea spallation ea hona joale, e nang le mocheso o phahameng oa ts'ebetso, tšilafalo ea mahlaseli a kotsi, le ho tetebela ho hoholo, 'me e ka fokotsa mocheso o sebetsang oa tube haholo le ho ntlafatsa ts'epo.

Baoji Winners e hlahisa haholo-holo tungsten le molybdenum le thepa ea eona ea alloy 'me e ka etsoa hore e lumellane le litlhoko tsa bareki. Bakeng sa tlhaiso-leseling e batsi ea sehlahisoa, ka kopo ikopanye le rona (Whatsapp: +86 156 1977 8518).

Nako ea poso: Phato-02-2022