Re hlahisa Likhoele tsa rona tsa Mouoane tse Setseng – Ho Hlalosa Bokgoni bo Botjha ba ho Hlahisa Filimi e Nyenyane!

Re hlahisa Mokhahlelo oa rona oa BohlokoaLikhoele tsa mouoane– Ho Hlalosa Bokgoni bo Botjha ba ho Hlahisa Filimi e Nyenyane!,

Likhoele tsa mouoane,

Tlhahisoleseding ea Coil ea Li-Filaments tsa Tungsten

| Lebitso la Sehlahisoa | Li-filament tsa mouoane oa Tungsten |

| Bohloeki | W≥99.95% |

| Botenya | 19.3g/cm³ |

| Sebaka sa ho Qhibiliha | 3410°C |

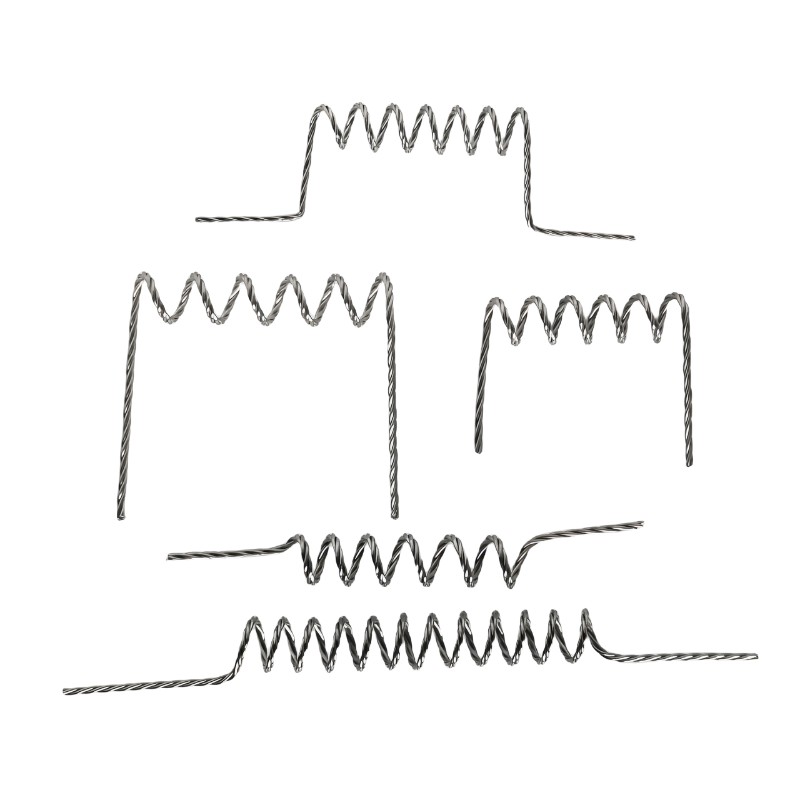

| Likhoele | φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, E ka fetoloa. |

| MOQ | 3kg |

| Ela Hloko: Dibopeho tse ikgethang tsa difilamente tsa tungsten di ka etswa hore di tshwanelehe ho ya ka ditlhoko tsa hao. | |

Setšoantšo sa Mohlala

| Sebopeho | E otlolohile, Sebopeho sa U, E ka fetoloa |

| Palo ea Likhoele | 1, 2, 3, 4 |

| Likhoele | 4, 6, 8, 10 |

| Bophara ba Lithapo (mm) | φ0.76, φ0.81, φ1 |

| Bolelele ba Likhoele | L1 |

| Bolelele | L2 |

| ID ea Likhoele | D |

| Ela hloko: litlhaloso tse ling le libopeho tsa filament li ka fetoloa. | |

Melemo ea Rona

Likhoele tsa mouoane tsa tungsten tse hlahisoang ke k'hamphani ea rona li na le bohloeki bo phahameng, ha li na tšilafalo, phello e ntle ea ho boloka filimi, matla a tlase le theko e tlase, 'me li loketse lisebelisoa tse fapaneng tsa mouoane oa vacuum. Re boetse re fana ka lits'ebeletso tse fapaneng tse ikhethileng.

Tlhophiso ea Li-heater tsa Tungsten Filament

Re fana ka mehloli ea mouoane le thepa ea mouoane bakeng sa ho koahela ka PVD le ho koahela ka Optical, lihlahisoa tsena li kenyelletsa:

| Li-Liner tsa ho Chesa ka Li-electron Beam | Sehatsetsi sa Tungsten Coil | Tungsten Cathode Filament |

| Mocheso oa ho Fehla ha Mouoane | Thepa ea ho fetoha mouoane | Sekepe sa ho fetoha mouoane |

Ha o na sehlahisoa seo o se hlokang? Ka kopo ikopanye le rona, re tla o rarollela sona.

Tefo le Thomello

→TefoTšehetsa T/T, PayPal, Alipay, WeChat Pay, jj. Ka kopo buisana le rona bakeng sa mekhoa e meng ea ho lefa.

→Ho RomelaTšehetsa FedEx, DHL, UPS, thepa ea likepe, le thepa ea moea, u ka iketsetsa moralo oa hau oa lipalangoang, 'me re tla boela re fane ka mekhoa ea lipalangoang e theko e tlase bakeng sa litšupiso tsa hau.

Na o batla ho tseba haholoanyane ka lihlahisoa tsa rona?

Ikopanye le 'Na

Motsamaisi oa Thekiso oa Amanda│

E-mail: amanda@winnersmetals.com

Mohala: 0086 156 1977 8518 (WhatsApp/Wechat)

Haeba o batla ho tseba lintlha tse ling le litheko tsa lihlahisoa tsa rona, ka kopo ikopanye le mookameli oa rona oa thekiso, o tla u araba kapele kamoo ho ka khonehang (hangata nakong ea lihora tse 24), ehlile, o ka boela oa tobetsa "KOPA KHOTETSO"konopo", kapa ikopanye le rona ka ho toba ka ho re romela imeile (Imeile:info@winnersmetals.com).

Re hlahisa Mokhahlelo oa rona oa BohlokoaLikhoele tsa mouoane– Ho Hlalosa Bokgoni bo Botjha ba ho Hlahisa Filimi e Nyenyane!

Bokgoni ba ho Lokolla le ho Nepahala:

Kena bokamosong ba ho kenya filimi e tšesaane ka Li-Evaporation Coil tsa rona tsa sejoale-joale. Li entsoe ka lebaka la bokhabane, li-coil tsena li etselitsoe ho fana ka katleho e sa bapisoeng, ho nepahala le ts'epo lits'ebetsong tse fapaneng tsa ho koahela.

1. Sebopeho se Tsoetseng Pele sa Thepa:

Likhoele tsa rona tsa Mouoane li entsoe ka hloko ka thepa ea boleng bo holimo, ho netefatsa ts'ebetso e phahameng lits'ebetsong tse fapaneng tsa ho beha. Sebopeho se tsoetseng pele sa thepa se tiisa ho tšoarella, botsitso ba mocheso, le ts'ebetso e ntle ka ho fetisisa libakeng tse thata.

2. Ho Hlahisa ka ho Nepahala bakeng sa Lifilimi tsa Boleng bo Holimo:

Finyella lipente tse nepahetseng le tse ts'oanang ka Li-Evaporation Coil tsa rona. Hore na o sebetsa ka litšepe, li-alloy, kapa thepa ea tlhaho, li-coil tsena li nolofalletsa ho fetoha ha mouoane ho laoloang, e leng se fellang ka lifilimi tsa boleng bo holimo tse fihlelang litekanyetso tse thata ka ho fetisisa tsa indasteri.

3. Litlhophiso tse ka fetoloang:

Ka ho hlokomela ho ikhetha ha sesebelisoa se seng le se seng, Li-Evaporation Coil tsa rona li tla ka litlhophiso tse ka fetoloang. Iketsetse litlhaloso tsa coil hore li lumellane hantle le sistimi ea hau ea ho beha, ho netefatsa hore li lumellana hantle le litlhoko tsa hau tse ikhethileng.

4. Bokgoni bo Ntlafaditsweng ba Thermal:

Latsoa bokgoni bo phahameng ba ho futhumatsa ka dikhoele tsa rona tsa mouoane. Dikhoele tsena di entswe ho mamella mocheso o phahameng, di thusa tshebetsong e tsitsitseng le e tsitsitseng nakong ya tshebetso ya mouoane, e leng se fokotsang kotsi ya ho fetofetoha ha mocheso.

5. Litšebeliso tse Tenyetsehang:

Li-coil tsa rona tsa mouoane li fumana lits'ebetso ho pholletsa le mefuta e mengata ea liindasteri, ho tloha ho tsa elektroniki le tsa optics ho ea ho saense ea thepa. Ho tenyetseha ha tsona ho li etsa hore li lokele mekhoa e fapaneng ea ho beha, ho kenyeletsoa mouoane oa mocheso, mouoane oa mahlaseli a elektrone, le tse ling.

6. Kopanyo e Lokisitsoeng:

Ntlafatsa sistimi ea hau ea ho kenya lintho ka mokhoa o bonolo ka likhoele tse etselitsoeng ho kopanya ka mokhoa o se nang sekoli. Likhoele tsa rona tsa Mouoane li tsamaisana le likamore tse fapaneng tsa ho kenya lintho ka mokhoa o sa senyeheng, li thusa phetoho e boreleli le ho ntlafatsa katleho e akaretsang ea lits'ebetso tsa hau tsa ho kenya lintho ka mokhoa o tšesaane.

7. Tataiso le Tšehetso ea Litsebi:

Boitlamo ba rona katlehong ea hau bo fetela ka nģ'ane ho sehlahisoa. Itšetlehe ka sehlopha sa rona sa tšehetso sa litsebi ho u tataisa ts'ebetsong ea khetho ea coil le ho fana ka thuso ho ntlafatseng ts'ebetso bakeng sa lits'ebetso tsa hau tse ikhethileng.

8. Boiqapelo bo Lokiselitseng Bokamoso:

Lula u lebile pele tsoelo-pele ea theknoloji ka Li-Evaporation Coil tsa rona. Ha sebaka sa ho beoa ha filimi e tšesaane se ntse se fetoha, boitlamo ba rona ba ho etsa lintho tse ncha bo netefatsa hore li-coil tsa rona li lula li le ka pele ho mahlale a macha.

Phahamisa mekhoa ea hau ea ho boloka filimi e tšesaane ka katleho le ho nepahala ha Li-Evaporation Coil tsa rona - moo thepa e tsoetseng pele e fihlelang theknoloji ea sejoale-joale. Khetha li-coil tse hlalosang bocha maemo a bokhabane ho boloka filimi e tšesaane. Leeto la hau la ho ntlafatsa katleho le qala mona.